Many believe digitalization means making analog processes digital. But that’s not true. Digitalization means rethinking processes for a digital world.

Christine Regitz

22. July 2025

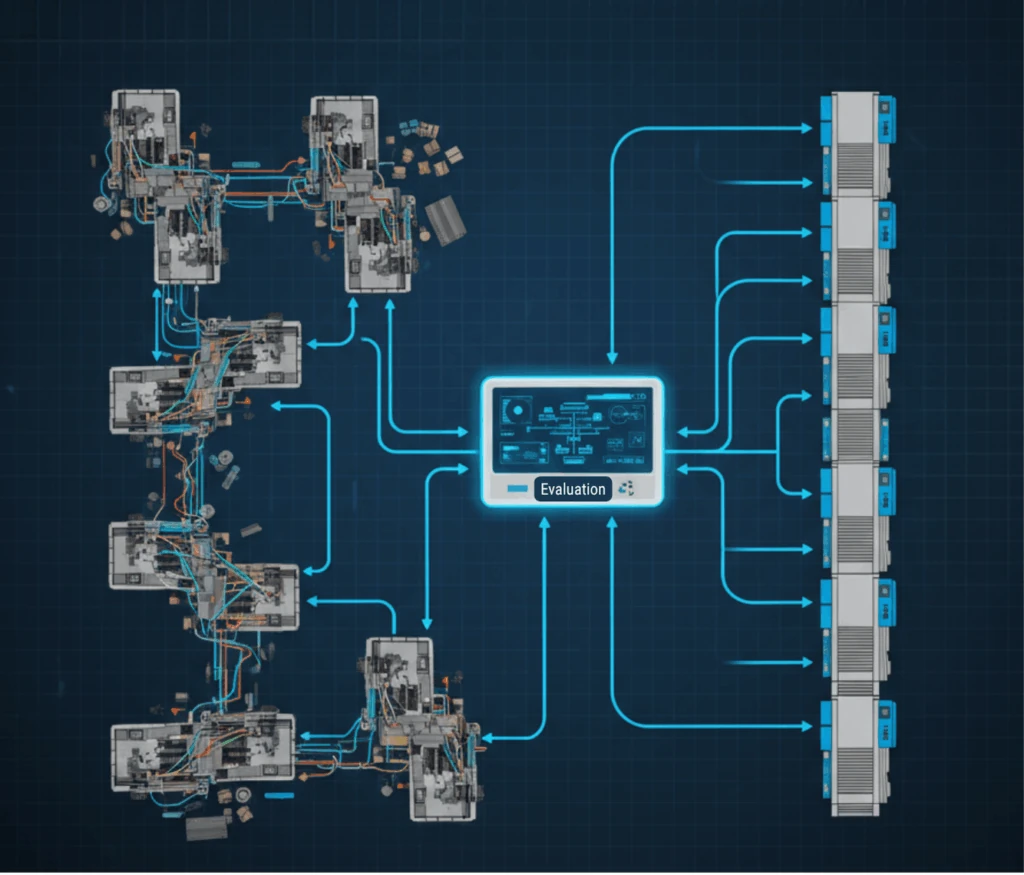

Production optimization software helps companies make their manufacturing processes more efficient and productive. It captures data from machines and workflows, analyzes it systematically, identifies weaknesses, and contributes to continuously ensuring product quality. Modern software solutions permeate nearly every area of manufacturing: from production planning and control to Manufacturing Execution Systems (MES), Quality Management Systems (QMS), Maintenance Management Systems (MMS), Warehouse Management Systems (WMS), and Business Intelligence (BI) and analytics tools.

So much for the theory. But as well-conceived as these concepts may be, practical implementation is rarely so straightforward. Production facilities often consist of machines from different generations that have grown over the years. Their interconnection follows no standard—instead, it has developed individually from operation to operation. Then there’s the human factor: employees bring vastly different experience levels, and critical processes often depend on the knowledge of specific individuals. Reliably ensuring consistent performance in this reality becomes a genuine challenge.

This is precisely where the conventional approach to production optimization reaches its limits. Rather than applying ready-made solutions to complex realities, we should first understand how software can truly support these organically grown structures and human factors. Only then do optimization solutions emerge that work not just on paper, but in practice.

The decision to adopt production optimization software is made quickly—but successful implementation is an entirely different challenge. From our experience, we’ve learned: The evaluation process must account for organically grown structures and individual circumstances from the very beginning.

The crucial question isn’t whether software theoretically offers all the desired features, but whether it harmonizes with your existing machine landscape, your processes, and above all, your team. The best software fails if it ignores how experienced employees work or unnecessarily complicates proven workflows.

Our philosophy is clear: Software doesn’t replace people—it empowers them. Production optimization only works sustainably when software is designed as a tool that extends your employees’ expertise, not bypasses it. The art lies in preparing complex data in a way that enables experienced production workers to make better decisions.

During evaluation, you should therefore ask: Does the software support your teams’ daily decisions? Does it reveal connections that were previously hidden? Good production software turns good employees into even better ones—it doesn’t make them redundant.

From our perspective, every evaluation should honestly answer these questions:

The best production optimization software is the one that empowers your people and understands your specific challenges. Not the one with the most features, but the one that fits you best.

If you’re wondering how these principles apply to your specific situation—our founders are happy to share their experiences in a free expert consultation.