01. July 2025

A case study on reduced downtime and smarter processes in end-of-line packaging.

Boosting efficiency is a central goal for modern manufacturing — yet with high-volume products like bottles, buffer storage is rarely an option. That means disruptions in end-of-line packaging often bring the entire line to a standstill.

Complex processes, unclear error messages, and missing technical know-how quickly translate into lost production time. Operators walk back and forth between different levels and machine sections because signal lights don’t clearly indicate the source of the issue. At the same time, many logistics employees lack the training to identify root causes and fix problems on their own.

These challenges are widespread across the industry: in many production lines — especially in the food and beverage sector — they occur on a daily basis. The same bottlenecks were a key barrier to greater efficiency in our project with Rotkäppchen-Mumm.

So how can typical disturbances in end-of-line packaging be resolved faster — and real production efficiency achieved?

The answer lies in a digital approach that makes experiential knowledge systematically available.

Together with Peerox, Rotkäppchen-Mumm implemented a solution that proves efficiency gains are possible — through smart knowledge management, targeted root-cause analysis, and software-based support for operators.

With the introduction of MADDOX, handling disruptions in end-of-line packaging at Rotkäppchen-Mumm has been fundamentally transformed — all in the name of sustainable efficiency gains. When a disruption occurs, it is no longer indicated solely by a signal light; it is also displayed visually on a large touch panel. Employees can click directly on the alert and immediately receive suggestions for possible causes as well as the affected equipment section.

What makes it special: If the employee on site is unsure of the cause, they can use the adjacent tablet. There, they access a structured knowledge base — including images, videos, and concrete solution suggestions, most of which were entered by their technical colleagues. This way, experiential knowledge can be retrieved, supplemented, and applied directly at the point of action.

Once the employee confirms a solution, this information is fed back to further improve the system: MADDOX’s AI-powered search algorithm learns continuously, linking causes with solutions. At the same time, the disruption is documented — including the human-assigned root cause.

The result: fewer unnecessary trips, faster response times, and measurable efficiency gains on the production line.

Dieter from logistics is delighted, since he now deals with problems less frequently and avoids unnecessary walking. He prefers to earn his cardio points on his fitness tracker while cycling outdoors rather than climbing stairs next to the noisy palletizer.

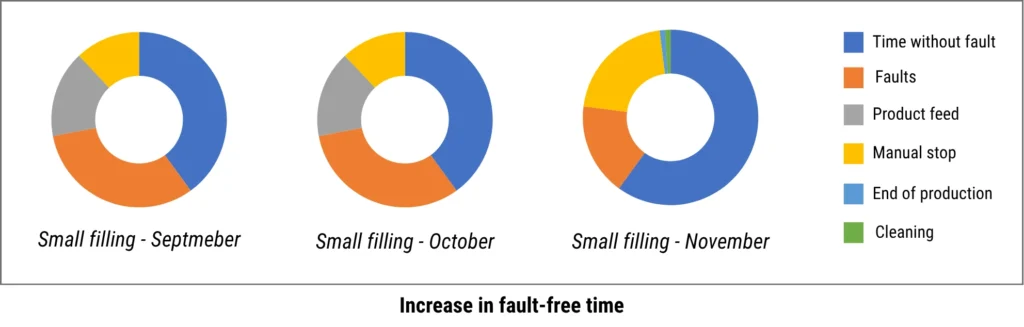

The pilot project with Rotkäppchen-Mumm clearly demonstrates that efficiency gains are not just a goal — they are a measurable result. The proportion of “uptime” in the monitored lines increased month by month after MADDOX was implemented — especially noticeable in the small-bottle line (Piccolo bottling) in November, where the highest share of machine runtime was achieved without disruptions.

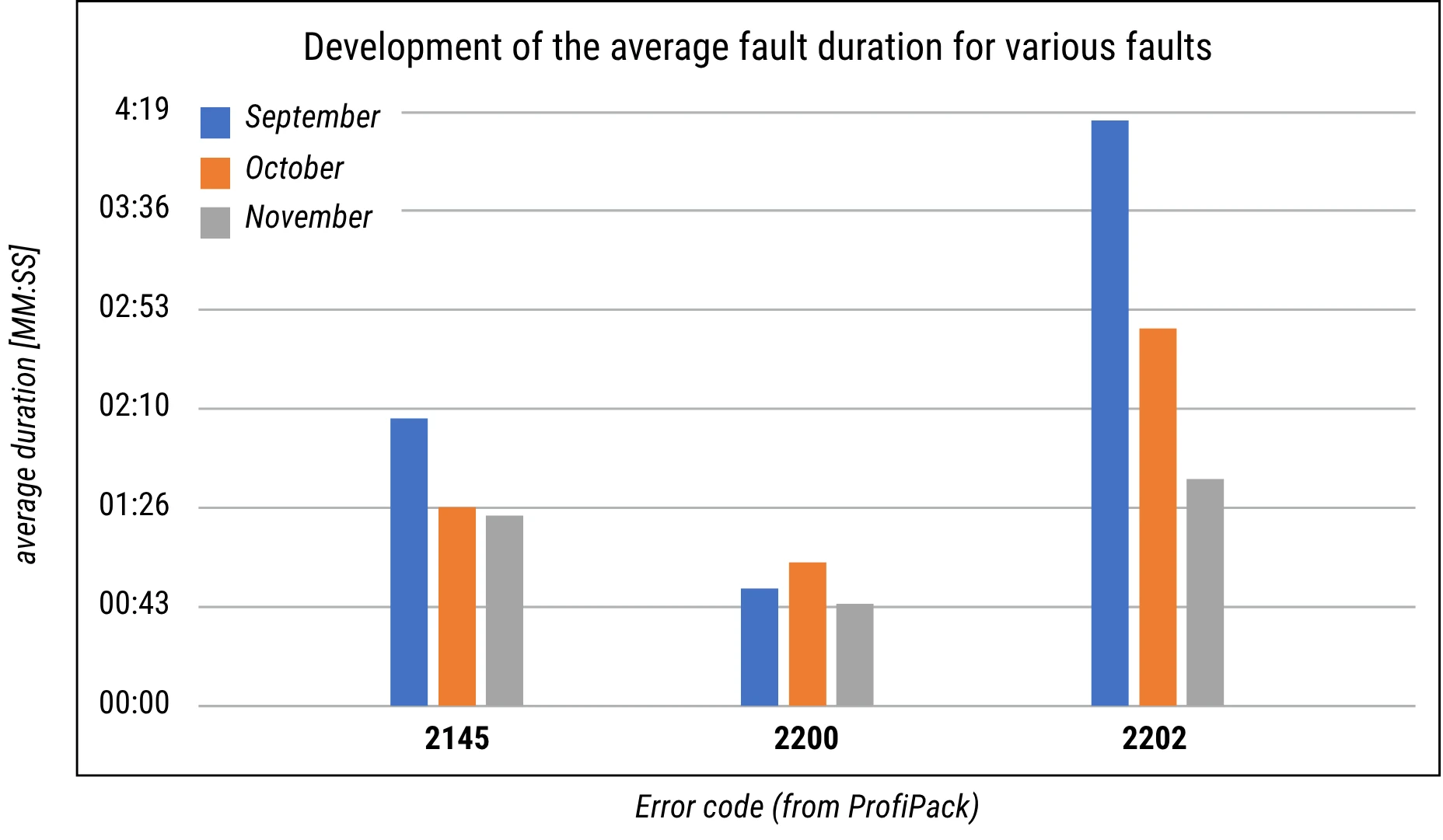

Further evidence is provided by the development of average downtime for frequently occurring error codes. The following chart illustrates how the duration for errors 2202 and 2145 decreased significantly over a three-month period. For these common disruptions in particular, the use of MADDOX led to faster responses, more targeted actions, and a noticeable relief for employees.

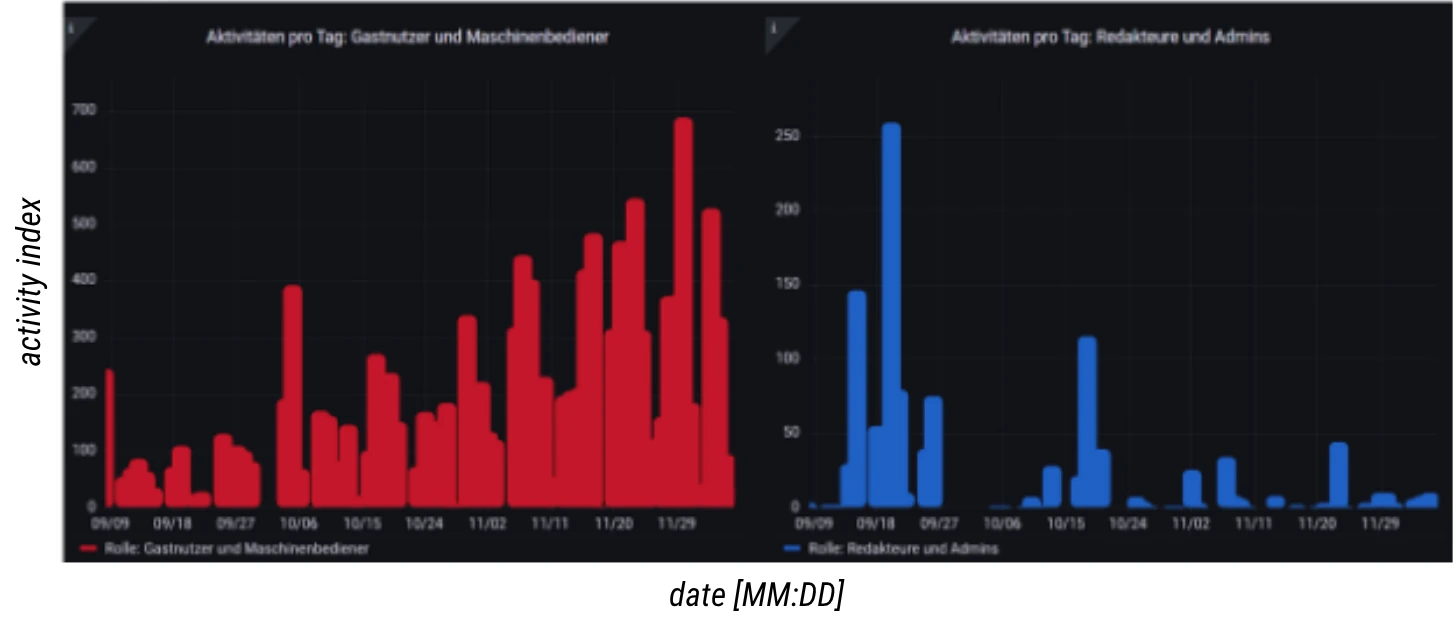

These improvements were not only visible but also actively utilized: the consistently high system usage and positive feedback demonstrate the solution’s practicality in daily operations — from operators to technical staff.1

When knowledge flows properly, the production line runs more smoothly.

Want to find out how MADDOX can also reduce downtime and streamline processes in your production? Book a no-obligation expert consultation now — and discover how smart knowledge management drives real efficiency gains.

1) Peerox uses the presented analyses together with its customers during the pilot and implementation process of MADDOX. This ensures that the system rollout does not follow a “do and hope” approach, but is data-driven, controlled, and predictable. Any acceptance issues, need for additional training, or other obstacles arising during the change process can be immediately identified and addressed. The data analysis and usage are conducted according to an anonymization procedure developed in collaboration with employee representatives.

Production Downtime and Operator Response: What Causes Slow Reactions – and How to Reduce Downtime.