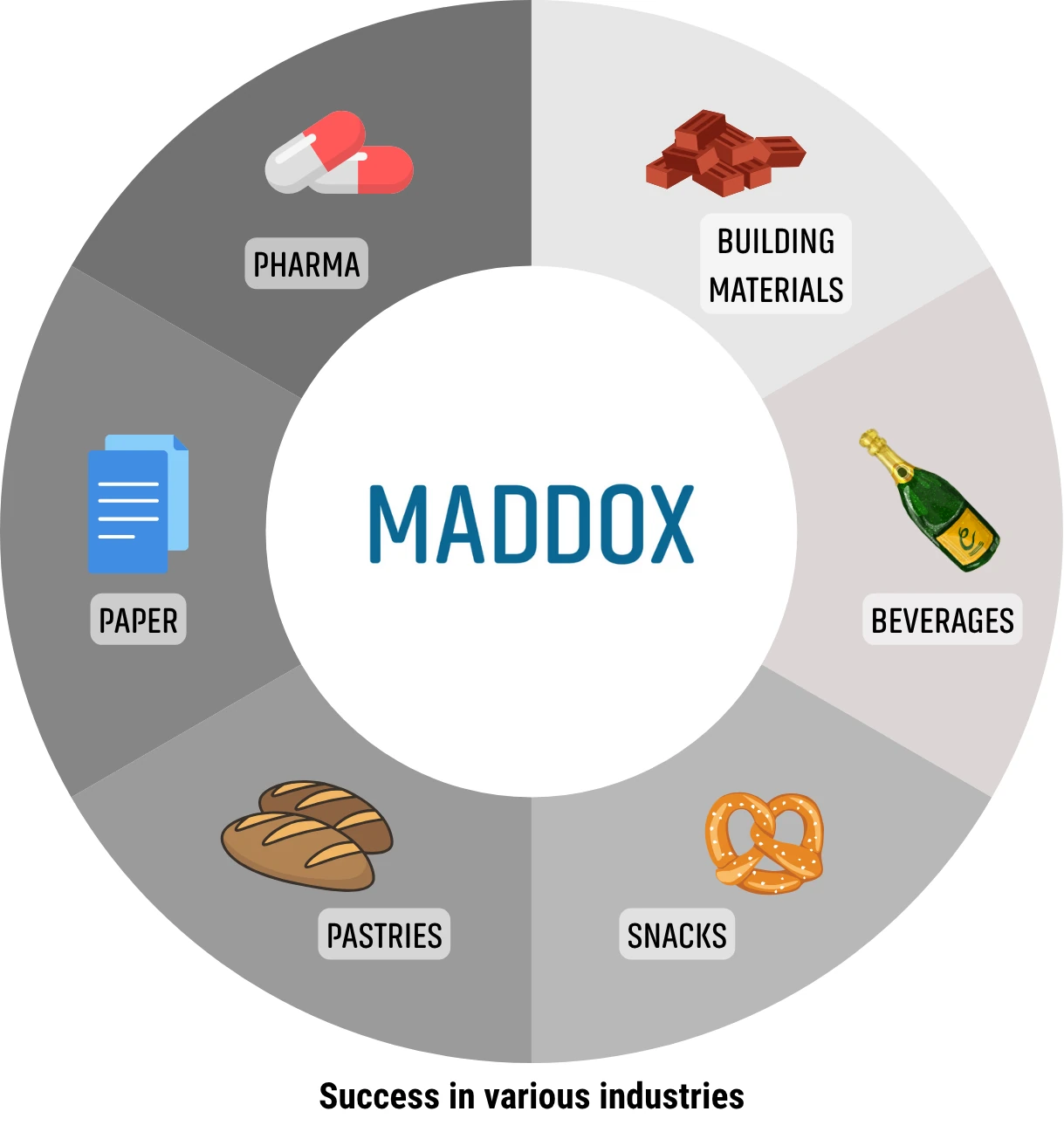

MADDOX stands for proven knowledge management that has demonstrated its value across a wide range of production environments. Real-world examples show that, regardless of industry or product, fast onboarding, high employee acceptance, and measurable improvements in efficiency and disruption prevention are achievable.

In the pharmaceutical environment, strict regulations coexist with the expectation of maximum efficiency. Three of the largest pharmaceutical manufacturers use MADDOX to systematically document operational knowledge and make it accessible at any time. This not only enhances process reliability but also enabled an increase in OEE through more targeted root-cause analyses of deviations.

Short cycle times, frequent product changeovers, seasonal peaks: in snack production at Lorenz, the challenge is to maintain stable output despite changing demands. MADDOX helps identify common sources of error early and provides standardized solutions. This keeps the production line moving – even when staff rotate.

In the sensitive final packaging of sparkling wine and wine, every second counts, as buffers are limited and disruptions in palletizing can quickly bring the entire bottling line to a halt. Rotkäppchen-Mumm implemented MADDOX to support logistics personnel in troubleshooting. The result: by empowering existing staff, hiring additional machine operators for the final packaging was unnecessary. Even without specialized personnel, MADDOX guidance significantly increased the efficiency of the palletizing system. The notably high interaction rate is a clear signal that employees recognize the added value and actively use the system in their daily work.

At Dr. Quendt, traditional recipes meet modern technology. The frequent product changes in bakery production demand flexibility and know-how. MADDOX provides structured procedures for changeovers and helps new employees get up to speed quickly – a real advantage in a dynamic shift system.

The strong focus on Christmas baked goods presents a particular challenge. Over the course of the year, the workforce doubles and halves due to seasonal employees. New staff must adapt within days to the demanding combination of natural products with variable properties and complex, highly automated equipment. Training is further complicated by language barriers. Here, MADDOX, as a knowledge management system with automatic translation, offers significant advantages.

In the paper industry, even small deviations can lead to high scrap rates or machine downtime. MADDOX helps Leipa and two other paper manufacturers systematically capture recurring disruption patterns – and provides solutions for all shifts. As a result, unproductive downtime has been reduced and response times significantly shortened.

Large systems, abrasive materials, rotating shifts: at Knauf, knowledge about the sometimes highly specialized equipment is often tied to individual employees. With MADDOX, experiential knowledge is made accessible regardless of location. Whether dealing with disruptions or startup processes, operators find quick answers exactly where they are needed – at the machine.