16. July 2025

Despite high levels of automation, production downtime still occurs. The reasons are diverse. In addition to operator errors, hard-to-measure product and packaging properties (e.g., the random distribution of nuts in chocolate or varying carton moisture) can cause process fluctuations. Because it is generally more economical —but more error-prone— to run processes as close as possible to the physical limits, these fluctuations often lead to micro-stoppages that operators must address.

This article explains why there are significant differences in operators’ response capabilities and how the duration of unplanned production downtime can be significantly reduced by intelligently combining automation with human knowledge.

The idea of a completely error-free, self-regulating production process is persistent, yet reality shows that even in highly automated plants, humans remain an indispensable factor for success. Production downtime often occurs precisely when this fact is overlooked.

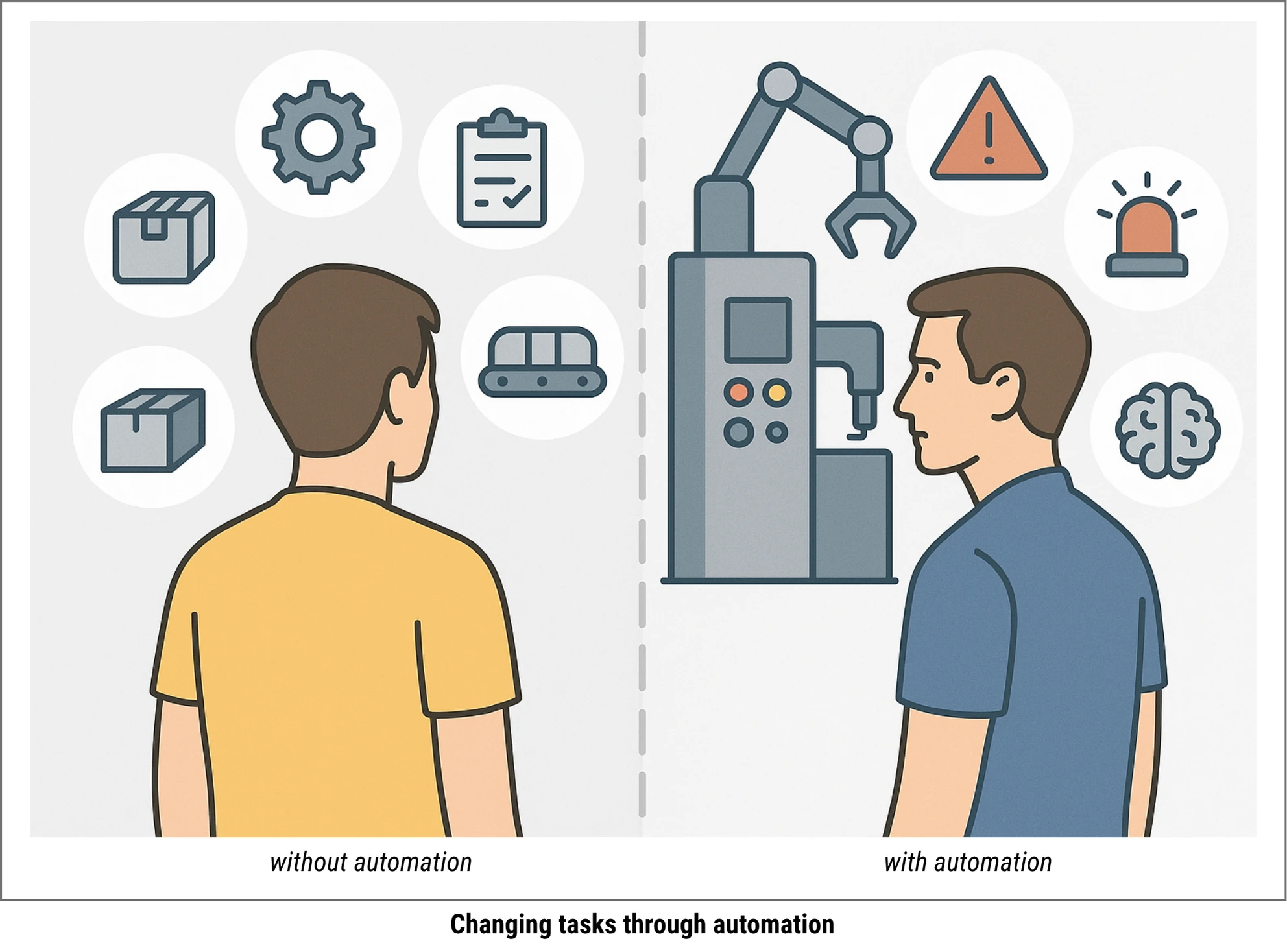

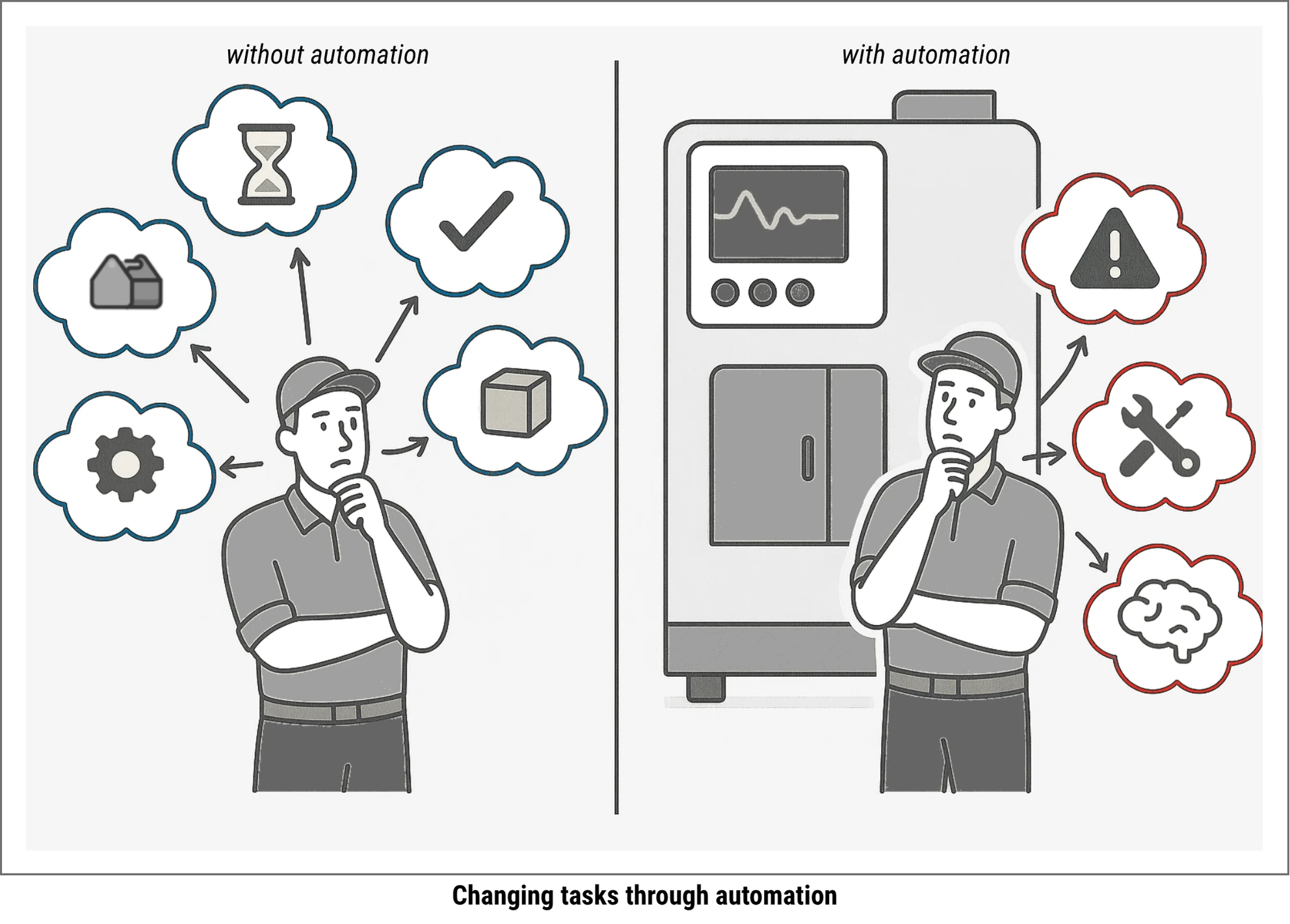

For a long time, the division of tasks between humans and machines followed a simple rule: technology handles everything that can be reliably automated, while humans take care of flexibility and improvisation.

Today, however, a new conflict emerges: the more tasks machines take over, the less often operators need to intervene – yet when they do, it is usually in particularly critical situations.

The problem: these rare interventions require full attention, rapid analytical skills, and comprehensive process knowledge – all of which suffer when humans are scarcely involved in process control over long periods.

A human-machine system is more than just the sum of its parts. When tasks are removed, performance in the remaining tasks is directly affected. This connection is often underestimated in practice – with noticeable consequences: delayed reactions and longer production downtime during critical moments.

If you want to learn how to better support your operators in critical situations and prevent production downtime, we’d be happy to show you live.

Book a free, no-obligation demo now and see MADDOX in action!

Peerox Delivers: Boosting Efficiency at Rotkäppchen-Mumm with AI-Driven Knowledge Management