16. September 2025

„Every successful company has tackled at least one significant challenge.“

“Every successful company has tackled at least one significant challenge.”

This statement can also be looked at from the other side: if a company has only solved relatively simple problems—ones that most others can solve too—then it likely has just one problem: competition.

Competition drives prices down and erodes margins.

How solving difficult problems creates successful companies is shown by many examples in the market: Tesa and Tempo managed, through outstanding marketing for otherwise very simple products, to make their brands synonymous with entire product categories. Novo Nordisk addressed a long-standing challenge in pharmaceutical research with the weight-loss drug Wegovy. SpaceX solved the technical challenge of reusable rockets, enabling price leadership while maintaining high margins. Similarly, Ford achieved its goals at the beginning of the last century by solving process and HR problems (introducing the assembly line and offering far above-average wages to skilled workers). The more of these difficult problems you solve (e.g., Apple: technology and marketing), the better your company is positioned.

If, in your daily production operations, you have identified (experience-based) knowledge as a—undoubtedly difficult—problem, you should first evaluate whether an outstanding solution could give you the potential to leave your competitors far behind. Could you achieve price leadership with far fewer unplanned process disruptions than the industry average (while maintaining or increasing margins)? Could you become the leader in delivery times, reliability, and/or quality? Would you be the only company in your industry spared from the workforce crisis caused by demographic change? Could you establish a highly knowledge-intensive production at locations with extreme skilled labor shortages but very low labor costs?

If this potential for success is limited or non-existent in your situation, you should focus on other difficult problems (technology, marketing, etc.) to position your company successfully in the market or defend its position. This does not mean you should neglect the impact of knowledge on your company’s success. You will still need committed specialists, a functioning internal documentation system, and effective onboarding. But it is sufficient to implement market-standard solutions reliably, while focusing your energy on problems in other areas.

If, however, you see an opportunity to achieve a pole position in your industry by managing knowledge effectively in production, then internalize the following statement:

“Above average is far from enough!”

For the described effects to really take hold, you need to be the best—or at least among the top 5%. There is only one way to get there: focus! You must concentrate your resources, creativity, and energy on exactly one goal. Otherwise, at best, you will be very good in many areas but nowhere outstanding enough to leave everyone else far behind.

“Okay, sounds reasonable. Then let’s focus on the topic of ‘knowledge in our production.’” That is not yet focus; it is like someone wanting to become a winter sports world champion. Curling, ski jumping, or luge?

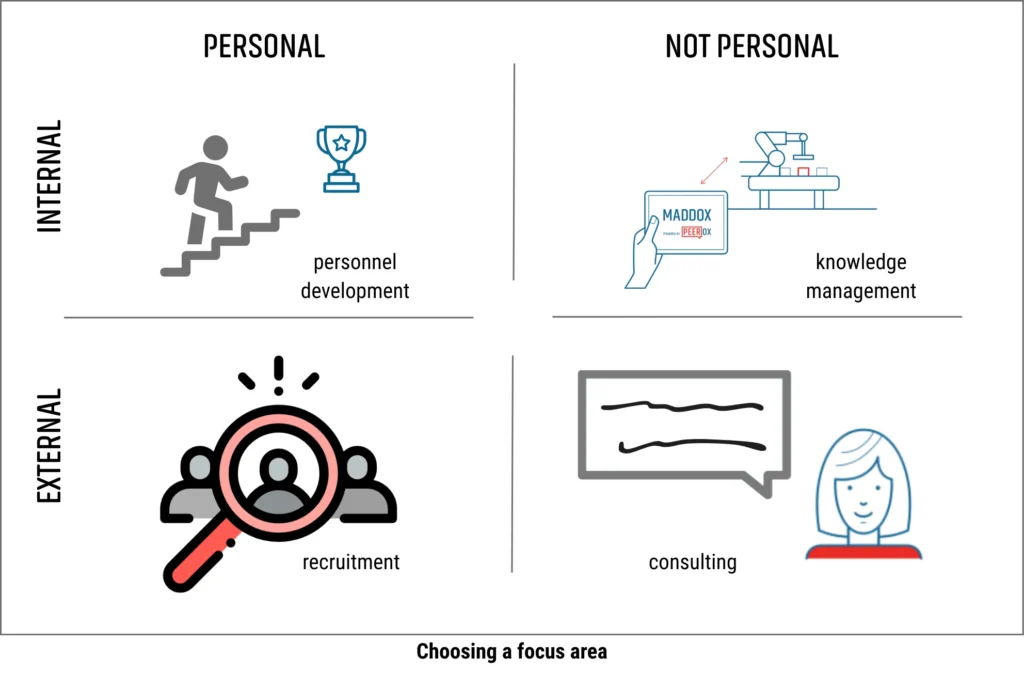

To develop a world-class solution, you need to tackle a very specific problem that fits your situation. For the topic of knowledge in production, the following matrix provides a useful guide:

The boundaries between the different areas are naturally fluid. For example, effective knowledge management supports employee training, and recruiting ambitious staff significantly contributes to successful personnel development. Nevertheless, for the sake of focus, you should choose one area as your primary focus.

This isn’t about an annual training program or the chance to earn a master’s degree alongside work. Your company has a reputation as the ultimate hands-on academy. Anyone who wants to learn and gain real experience after graduation comes here. There are outstanding trainee programs, and your employees enjoy an elite reputation within the industry, with only a small fraction of applicants ever being accepted.

You attract highly motivated applicants and can select the best talent. They view the opportunity for professional and personal development as a key benefit, allowing you to maintain lower personnel costs. Often, a positive momentum develops within the team, driven by the desire to live up to the company’s elite reputation.

The challenge lies in retaining employees once they have fully developed their skills.

You offer an outstanding overall package tailored precisely to the skilled workers you need. A competitive salary is part of it, but it is usually not the most important lever. Shift-working parents appreciate childcare that exceeds state standards, with hours tailored to their needs.Experienced professionals are often open to leaving due to a negative company culture or poor leadership. Ensure you provide a top-notch environment and excellent leaders in these areas. To make these benefits effective, you need a recruiting team that is strong both in communication and process management.

You already hire highly skilled professionals and can leverage their expertise without significant additional investment.

Even if salary isn’t the deciding factor, personnel costs can still be quite high. Employees who were willing to join your company may leave again if the surrounding conditions no longer meet their needs.

You benefit immediately, with knowledge tailored precisely to your problem and only to the extent required, from the expertise of the best specialists. Gaining an edge over other companies comes from knowing the top consultants in the market and maintaining a coordinated network that creates synergies between various specialized consulting and service providers. You excel in the discipline of “knowing the right people for every situation.” Some problems can be permanently solved through technical or organizational adjustments. Other solutions need to be embedded by employees, creating a direct link to personnel development. Taken further, however, you can also purchase these solutions as a service, without having to build the necessary structures and content yourself.

Generally well-suited when solutions are needed quickly or when internal resources are not available to implement other options.

The expertise does not become embedded within your company, creating dependencies that can lead to high costs over time.

Your company has an optimal system in place that captures and makes knowledge readily available. Processes for knowledge documentation are well established and actively practiced. Anyone looking to solve a problem turns to the knowledge management system as their first point of reference. With less emphasis on technical expertise in recruiting, you can focus more on important soft skills while still maintaining a sufficiently broad talent pool. Scaling is no obstacle; across shifts or sites, your knowledge management system supports employees in every situation.

This is the only one of the four areas in the matrix where knowledge truly becomes part of the company’s intangible capital. Unlike people-dependent approaches, your know-how is not threatened by turnover or demographic changes. With a user-friendly knowledge management system, even non-specialist employees (and thus lower personnel costs) can deliver strong performance after a short onboarding period.

The knowledge management system must first be filled with content and firmly established. For the system to take hold and gain acceptance from everyone, excellent change management and an initial ramp-up period are essential.

If you’d like to learn more, you can book a free consultation and discover how we at Peerox have developed a solution for efficient knowledge management in production.

Industry 4.0 Requires Proven Knowledge Management – How Leading Manufacturers Are Already Successfully Implementing It.